Editor's note: The class is currently in an area with extremely limited Internet access. Once they are in an area with better connectivity, we will add more to this post.

2nd editor's note: The class got to an area with better Internet. So we can add the latest chapter to the blog.

18May2019

|

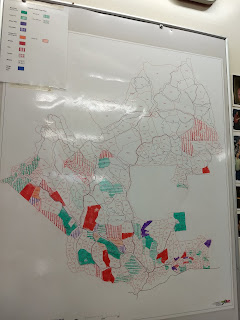

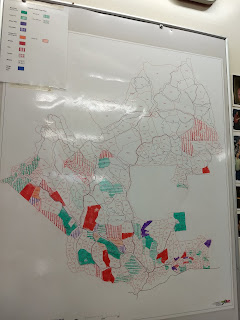

| Overview of Mt Linton farm broken down into

paddocks |

We started this morning in Te Anau

at our hotel with breakfast served, then departed our hotel and traveled

through to Mt Linton Station. This station has 13,000 hectares, and is the

largest privately owned operation with 105,000 stock units. With having 13,000

hectares, they have over 300 km of maintained road throughout the property. This

station is broken down into: 74,000 sheep, 120 dogs, and 3,000 cows.

|

| The 12 shearing stations in their main shearing

barn |

Mt

Linton produces 250,000 kg of greasy wool each year. They shear 40,000 sheep

and 30,000 lambs twice a year (or every 6 months). The wool is then contracted

through New Zealand Merino wool. They had 12 shearing stations and it can hold

7,000 ewes under the shed for weather related purposes. Having the shed is good

for making management easier for the shearers. They get 2.5 kilograms of wool

per shearing. They breed for maternal and terminal traits. Romney and Texel are

the maternal breeds, and the Suftex is the terminal breed. They do not

outsource their rams, they only use their own genetics.

| | |

| The sorting and packing area for the wool |

|

| This is the working/holding area for the sheep. |

Mt

Linton Station primarily raises Angus cows. They focus on good marbling being

raised on only green grass getting transitioned over from grass to finish on

kale and fodder beets. They are finished at 18 months, and then are sent away

from May to October. They breed their own bulls, and get genetics imported from

Australia. Their loading system is very efficient as they have a stack loading

chute. They did this so they do not have to use the ramp of the trailer so the

cattle don’t slip and get injured. They have had success with not having

bruising on the carcass.

|

| Looking down from the top ramp of loading chute |

Both the cows and the breeding ewes

are getting one round of AI (artificial insemination) then get put out with a

cleanup bull or ram. All of the breeding stock has EID tags in their ear to

keep records of the history of that animal. They have a 65:35 sheep to cow

ratio on their station.

|

| Overview of cattle working facil |

Throughout

the year they have 16 full time employees, and then during the summer they get

up to 25 employees. They provide housing on site to the shepherds and feed a

meal to them also. This operation encompasses a full time mechanic and a

fencer.

|

| The two deck loading chute |

They

train their sheep dogs on voice command and on whistle command. With having 120

dogs, each employee gets assigned dog(s) to further train and use them to herd

sheep. Our tour guide, Jacob, a stock manager, has 12 dogs of his own.

|

| Landscape of Mt Linton station |

After

our tour, Heather had prepared us lunch which consisted of a whole lamb roast

with three different salads and peppers. She had also provided us with a fruit

skewer, a chocolate cookie, and a carrot cake. After thanking our hosts, we

departed for a three hour bus ride to Miller Flat where we met our farm stay

hosts for the evening.

-Sidney, Anthony, Nicole

|

| Paddock of sheep |

|

| Paddock of cattle |

Comments

Post a Comment