|

| Sue

Rollinson providing coffee, tea, and snacks for the students before the tour. |

|

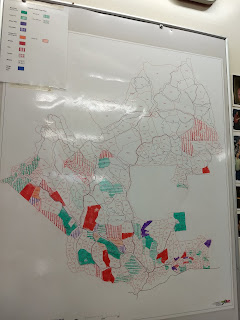

| This

is the layout of the Rollinson dairy operation. |

Our day started off with a delicious breakfast at the Hotel

Ashburton. After we were full, we jumped on the bus and made our way to Ted and

Sue Rollinson’s dairy farm to learn about their operation. Tom Hannigan is the

sharemilker on this farm who educated us on the history and current production

status of the Rollinson’s dairy. Diving into the history of the dairy, we

learned that Tom and Sue viewed this location in the South Island as an

opportunity to establish a dairy farm on the land in 1981.

|

| Students

walked into the paddock to visit the cows and check out the irrigation system. |

They wanted to

implement irrigation into their operation. They started out with 400 dairy cows

which was a lot during this time. They were able to double their herd size due

to the irrigation and improved the quality of the grass. Thanks to the

improvements of irrigation, Rollinson’s have now increased their herd size to

1,500 head.

|

| Cows

in holding pen, waiting to enter the milking shed |

Currently, they like to run smaller sized cows weighing about 450

kilos, because the cows do a lot of walking from the paddocks to the milking

shed every day. Even with their larger sized herd, this operation is the only

one to use one milking shed. When they first started the farm, they needed to

plant 40,000 pine trees to help cut down on the hot winds which was killing the

grasses, but, unfortunately, a huge wind storm knocked down most of the trees.

They later invested in pivot irrigation on most of their land, and they utilize

fertilizer on their grass paddocks which is planned around the cattle grazing.

The cows are provided a cheap supplement when the grass isn’t growing to ideal

levels to ensure that milk production remains at high levels. Rollinson dairy

breeds their cows to have the best genetic potential for higher milk production,

so their cattle are putting out an amount of milk compared to their body weight.

Therefore their cows produce 430 kilos of solids per cow, helping the milk

industry to export about 95% of milk products. One interesting fact is that the

New Zealand dairy industry sells based on higher protein and higher fat

contents rather than on volume like in the United States.

|

| Cows

being milked in the rotary parlor |

The Rollinson’s breeding system includes crossbreeding

Holstein Friesians with Jersey cows to get the best first cross possible and

maximize on hybrid vigor. This farm utilizes artificial insemination breeding

and then runs the cows with 30 bulls. We then learned that this operation herd

tests their cows 4 times a year to evaluate their overall productivity and cull

those that don’t meet the standards.

|

| Tom

Hannigan teaching us about the fodder beets & how they are fed to the cows. |

Then we hopped on the bus to visit their fodder beet field

which is similar to sugar beets except these will grow more above ground than

sugar beets will. Since these beets are low in protein, they need to supplement

protein for the cows to receive the required amount. Fodder beets have 16-17%

dry matter. These beets need to be supplemented to the cow’s diet in a gradual

manner due to the high levels of sugar which could cause acidosis if eaten in

high amounts. Therefore, it usually takes about three weeks to transition,

resulting in large weight gain and improvement in their body condition score.

Fodder beets are common during the cow’s diet while she is in her dry period

until she begins to calf.

|

| Students

exploring the huge fodder beets in the field. Some even taste tested the

produce! |

|

| Ian

and his son William explaining their cropping operation |

After lunch, we made our way to Akaunui Farm owned by Ian

and Diane McKenzie which is a 600 hectare mixed arable and livestock operation

including a small dairy herd, all under irrigation. Some of the produce grown

on this operation include milling wheat, perennial ryegrass seed, and a variety

of vegetables all on a 3 year rotation system. In the ryegrass paddocks, they

fatten roughly 5,000 lambs during autumn and winter months. To keep their lambs

in, they have a 4 wire fence which runs 8,000 volts. This farm has 350 dairy

cows which are milked from August to May. They are milked 3 times every 2 days,

and while in the milking shed they are fed a little bit of grain to keep them

content. The goal of this farm is to have the cheapest way to produce milk. It

takes about an hour to milk all 350 cows and this dairy doesn’t use a rotary

shed due to their high maintenance and cost. One cool fact we learned on this

visit was about pig production. The farm raises a small amount of pigs which

are sold to locals.

|

| Ian

McKenzie’s sheep mob grazing in the paddocks. |

|

| Listening

to Ian McKenzie explain the milking procedure. |

|

| Ian’s

shearing shed which can hold up to three shearers at a time. |

To end our day we went to our favorite grocery store to get

breakfast for the next morning and made our way back to the hotel for supper,

laundry, and socializing before bed.

Comments

Post a Comment